Commercial Building Application – Lakes District Health Board, Rotorua

An independently monitored trial was completed successfully at Lakes District Health Board. Power Solutions Limited, a Rotorua-based energy consultancy, undertook the trial between November 2015 and March 2016.

Test Outcomes

- 17% reduction in accumulated electrical load across the total system.

• 50% saving in water through controlled blowdown.

• Descaling chemicals eliminated.

• Carbon emissions reduced by 27,000kg CO₂-e

The trial

Rotorua Hospital has four water cooled chillers supplying chilled water at 6°C that is distributed throughout the hospital for cooling and dehumidification. The trial was conducted on Chiller Nos 3 and 4, both of which are Carrier Model 30XWO552P water cooled with compressors that use R134 refrigerant. Each chiller has a cooling capacity of 571kW each.

Pre-trial monitoring began on 26 November 2015 and ran for 12 days to set a baseline energy consumption. The DCI unit was also installed and operational from 17 December 2015 and the key trial ran until 4 March 2016 with continuous monitoring of key parameters, A second DCI unit was installed in parallel on 7 January 2016. Throughout the trial the existing chemical treatment of the cooling towers was isolated as the descaling process was taken over by the DCI units. pH was maintained between 8.5 and 8.8. Oxidation Reduction Potential, an indicator of corrosion, was maintained below 150mV.

Trial findings

Energy:

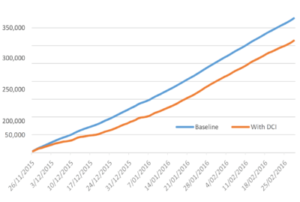

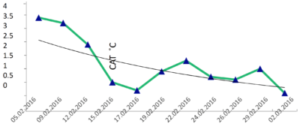

Energy consumption was evaluated using baseline and end of trial regression analysis formula, and a reduction of 17% was demonstrated in accumulated electrical load of the overall system. While condenser approach temperature (CAT) was not monitored from the beginning of the trial there was a marked improvement in CAT when readings were initiated in February 2016. CAT reduced by ≈3°C equating to approximately 9% reduction in compressor load. Occurring in the last month of the trial, it is reasonably assumed that the reduction in CAT could have been 4-5°C based on the DCI’s having been installed over a month prior and also the rate of reduction in CAT at the beginning of the logged period. This being the case of the gain in compressor efficiency would have been approximately 12-15%

DCI Trial Cumulative Total Electricity Use

Chiller 4 Condenser Approach Temp

Water:

Baseline consumption was 8.5 m³ per day, reducing immediately to 4 m³ per day due to smaller and controlled blowdown.

Chemicals:

Anti-scalant chemical usage ceased.

Carbon emissions:

At an estimated energy reduction estimated ast 197,000kWh/year and an emissions factor of 0.137kg CO₂-e, a reduction in carbon emissions of 27,000 CO₂-e was achievable.

System cleanliness:

It was noted as the trial progressed that scale was being loosened and falling off into the condenser water and presumed to largely come from the cooling tower media. While the loosening and removal of this scale in turn required regular regime of cleaning chiller strainers, this was seen as a positive step in the overall system cleaning and could be expected to continue for some time, progressively reducing until a clean system is achieved.