The DCI Device was installed with the Cooling Towers at a plastics molding factory in Singapore in 2011.

The challenge

Removing scales from the chilled water system used to cool plastic injection molding machines in the automated plastics plant. Inspections of the condensers and cooling towers revealed that both had very significant scale build up and poor cooling efficiency.

Test Outcomes

- 18.9 % Power saving from improved heat transfer and reduced pressure loss in the cooling water circuit.

- Higher productivity through reduced plant downtime.

- Improved product yield & quality due to efficient cooling.

- Reduced maintenance cost through elimination of chemicals and a substantial reduction in tubes/pipes cleaning cost.

- 50% reduction in Cooling Tower water blow-down volumes saving significant water bill costs.

Test Results

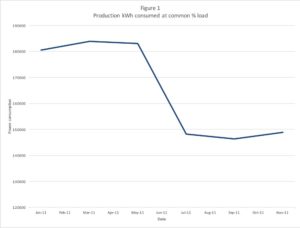

The test results, as shown in figure 1, were as follows:

January to March:

January to March:

Data was collected to establish a base line of performance before the DCI was brought on stream.

March to May:

Existing scale was softened giving a slight improvement in power consumption.

May to July:

The full de-scale effect kicked in removing water scale from pipes, tubes and cooling tower fill. Power consumption improved sharply until the end of June.

July to Sept:

Power consumption continued to reduce but at a lesser rate indicating most scale had been removed and the system was approaching the equilibrium point.

Sep to Nov:

Equilibrium point was reached.